State-of-the-Art Facilities

The Sikder Lab is equipped with cutting-edge fabrication and testing systems to advance regenerative implant research. We house high- and low-temperature Fused Filament Fabrication (FFF) 3D printers for biomaterial processing, along with a state-of-the-art bioprinter for developing live-tissue constructs. Our facilities include wet chemistry setups for material synthesis, multiple extruders for custom biomaterial formulation, and in-house developed platforms for applying controlled mechanical and electrical stimulation. Additionally, we have customized systems to measure electrical field generation in smart piezoelectric implants, enabling precise evaluation of their bioelectric properties.

We also maintain a fully equipped cell culture lab with biosafety cabinets, multiple incubators, microscopes, lyophilizers, and bioreactors, supporting the development and analysis of biologics and biologically inspired materials for regenerative applications.

Equipment

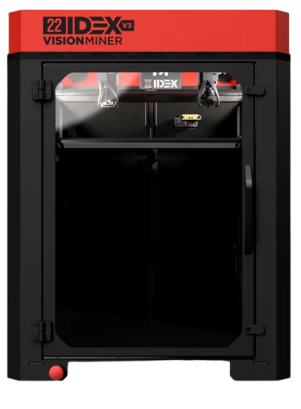

22 IDEX – Dual Extruder

This 3D printing system is designed for industrial and research applications. Its independent Dual Extrusion (IDEX) technology allows the use of two different print heads to work independently, enabling efficient multi-material printing or simultaneous printing of duplicate parts. The extruders can handle various materials, making the equipment versatile for complex projects.

INTAMSYS HT

This is a high-temperature 3D printer designed for industrial-grade materials such as PEEK, PEI, and other high-performance polymers. It features a heated chamber, high-temperature nozzles, and a build plate that enables precise and reliable printing of strong, heat-resistant parts. Its ability to handle advanced materials makes it well-suited for research applications and to produce parts that require durability and high thermal resistance.

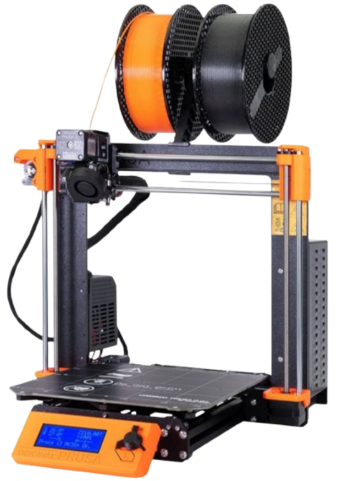

PRUSA

This 3D printer is known for its reliability, ease of use, and high-quality prints. It supports a wide range of materials, including PLA, PETG, and ABS, with features such as automatic bed leveling and user-friendly interface. The open-source design allows for customization, making it versatile for projects in prototyping, education, and small-scale manufacturing.

Filabot 3Devo filament maker

This filament maker is designed to recycle plastic into 3D printing filament. It offers precise control over filament diameter, ensuring consistent quality for 3D printing. It supports a variety of thermoplastics, making it ideal for sustainable manufacturing, research, and custom filament production in education, prototyping, and material development.

Cellink Bio X 3D Bioprinter

This 3D printer is designed for bioprinting applications, allowing for the precise fabrication of tissue and organ models. It features multiple print heads, enabling the use of various bioinks and materials simultaneously. With a user-friendly interface and high precision, it supports complec research in tissue engineering and regenerative medicine. In addition, this system offers temperature-controlled print heads and a steril printing environment, allowing for the fabrication of cell-laden constructs and making it ideal for biomedical applications.

CellScale Univert Mechanical Tester

This system is a versatile testing system designed for the mechanical characterization of small-scale materials and biological constructs. It offers precise control over compression and tension forces, making it ideal for evaluating the mechanical properties of tissues, hydrogels, and biomaterials. It also includes a water bath feature that maintains precise temperature control during mechanical testing to ensure accurate and consistent results for temperature-sensitive materials and biological samples. The tester’s features enable high accuracy testing in research areas such as tissue engineering, biomechanics, and material science.

Labconco FreeZone Freeze Dryer

This is a high-performance freeze dryer system designed for efficient and reliable lyophilization of samples. It features a robust refrigeration system with a low-temperature range down to -84°C, ensuring effective moisture removal from samples. The 12-port drying chamber allows for simultaneous processing of multiple samples, making it ideal for research applications where precision and sample integrity are crucial.