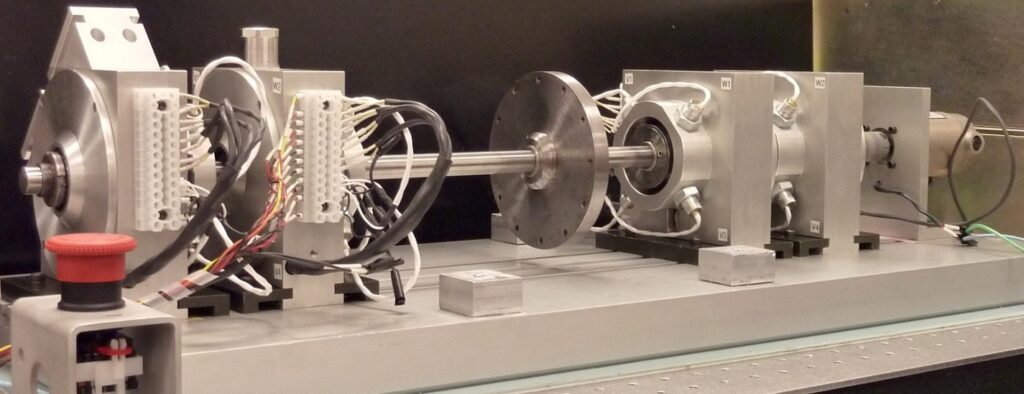

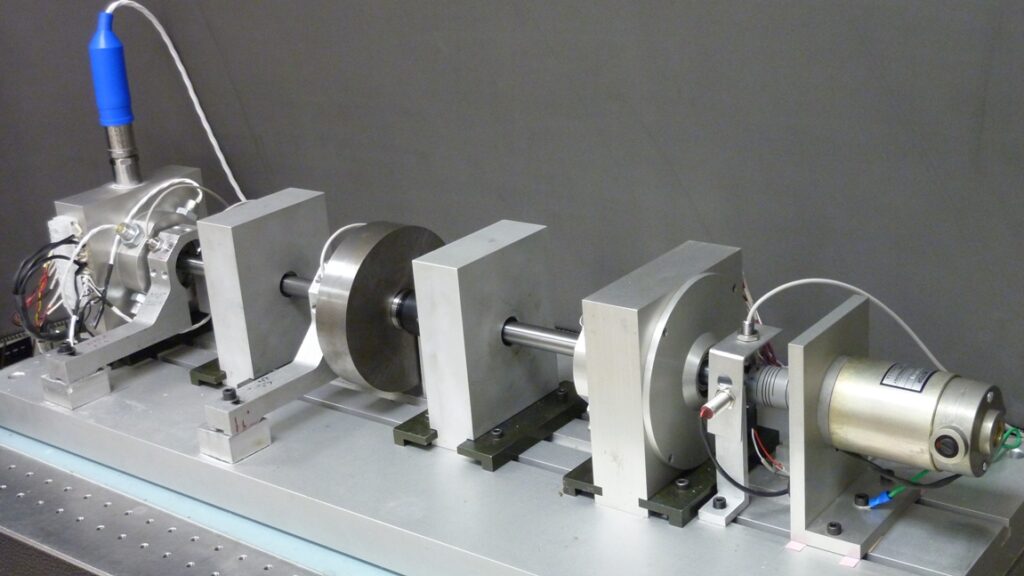

Crack Detection Rig

A rotordynamic test rig has been constructed at RoMaDyC for the purpose of crack detection research. The rig is also fit for studies in a wide range of fault detection and diagnosis. The test rig is modularly built so that good components can be tested and compared with components that have been intentionally inflicted with faults. For example, components such as shafts, disks, bearings, and couplings can be changed out to study cracks, cuts, rubbing, looseness, and misalignment.

The test rig is fully incorporated with state-of-the-art condition monitoring sensors and data acquisition. Also, the test rig is capable of multichannel excitation with magnetic actuators. The actuators enable injection signals for active condition monitoring methods. Active methods represent the next generation of health monitoring. The magnetic actuators are non-contact making them ideal for rotordynamic studies. The test rig has also been used in its static state for experiments on flexible structure health monitoring and fully levitated by the magnetic actuators for experiments on smart machines.