Detection of Cracks in Rotating Machinery

RoMaDyC » Areas of Research » Structural Health Monitoring

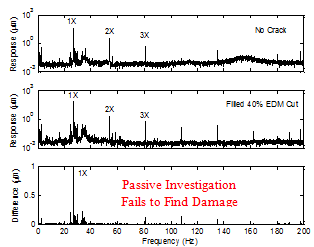

Traditional methods for rotor fault detection are passive. That is, the frequency spectrum of the rotor vibrations is analyzed for harmonics and subharmonics of the running speed. The presence of these extra frequency components indicates a problem. Unfortunately the passive approach is of limited effectiveness in detecting cracks because the harmonics of the running speed can be caused by several phenomena and cracks do not always increase them in a measurable magnitude.

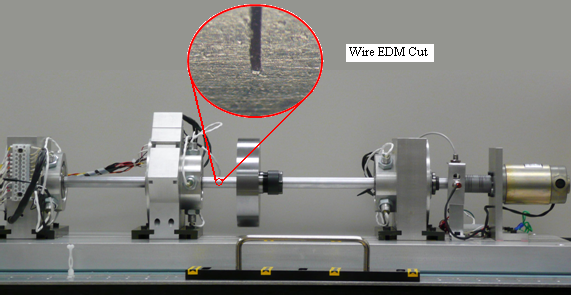

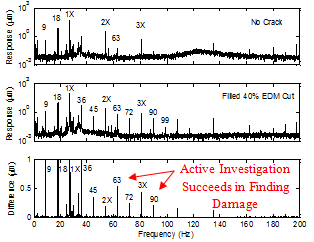

RoMaDyC is currently developing active crack detection methods in which an investigation signal is injected to the rotor system by non-contact actuators. The presence of a crack allows for nonlinear crosstalk between the running speed and natural frequency. The investigative signal may excite the combinational frequency to reveal the presence of the crack, if one exists.

Example test data showing the detection of rotating crack through active injection.

- Sawicki, J.T., Storozhev, D. and Lekki, J.D., “Exploration of NDE Properties of AMB Supported Rotors for Structural Damage Detection,” ASME Journal of Engineering for Gas Turbines and Power, Vol. 133, October 2011.

- Sawicki, J.T., Friswell, M.I., Kulesza, Z., Wroblewski, A., and Lekki, J.D., “Detecting Cracked Rotors Using Auxiliary Harmonic Excitation,” Journal of Sound and Vibration, Elsevier Ltd., Vol. 330, pp. 1365-1381, 2011.

- Sawicki, J.T., “Rotor Crack Detection Using Active Magnetic Bearings,” Solid State Phenomena, Special Issue: Mechanical Systems and Materials, Vol. 144, pp. 9-15, 2009.