Smart Machining

RoMaDyC » Areas of Research » Dynamics and Control

Smart machining is the application of cutting-edge smart machine techniques to traditional machining processes to achieve new levels of industrial productivity. A smart machine is one that incorporates some type of self monitoring and intelligent decision making process to automatically solve encountered problem while still on-line. Examples of problems which occur while machining are failure to hold part tolerance and machining chatter.

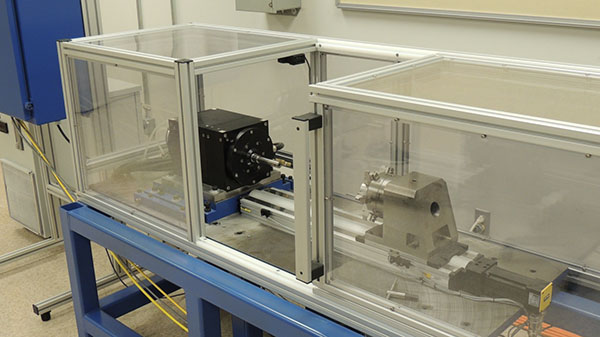

The RoMaDyC Center conducts research in the area of smart machining. One avenue of such research is the application of active magnetic bearings (AMBs) to the machining process. AMBs are mechatronic components which use position sensors and active feedback control to support a rotor with magnetic fields. In the case of smart machining, the rotor is a machining spindle and the feedback control is intelligently designed, not just for support, but to solve the problems which may occur while machining.

Examples of Smart Machining

- Robust Chatter Control

- Shaped Orbit Control

- Tooltip Tracking