Fuel Economy through Engine Oil Formulation

RoMaDyC » Areas of Research » Tribology and Lubrication

Due to increasing fuel costs and concerns over emissions created by the combustion of fossil fuels, every method to improve engine efficiency must be investigated. One way to improve overall engine efficiency is to reduce engine friction. An engine’s lubrication system plays a vital role in the reduction of this friction. Additionally, specialty engine oils can be developed to further reduce friction and improve fuel economy. These specially-formulated engine oils reduce friction by using low viscosity base oils and special additives which adhere to metal surfaces within the engine to lower coefficients of friction. This combination of low viscosity and specialty additives produce engine oils that have been proven to reduce friction and increase fuel economy across all lubrication regimes.

Mechanical testing is critical to the development of highly fuel efficient engine oil. The Lubrizol Corporation is an industry leader in the formulation of these engine oils and uses both industry standard and non-standard engine tests to evaluate fuel economy in a wide variety of engines. Non-standard tests are particularly important in industries that have a lack of standardization, such as the motorcycle industry.

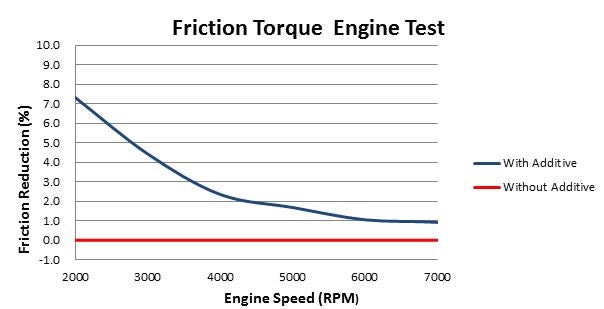

One newly-developed test rig uses an electric motor to drive a motorcycle engine. A high precision torque meter is mounted between the engine and motor. The torque meter is used to record data as the electric motor spins the engine to a variety of different speeds. The following figure shows data from two oils which are identical in every way except that one has a friction reducing additive while the other does not. Data has been normalized to show the percent friction reduction compared to the oil without the additive. The additive clearly reduces engine friction, especially at the lower speeds associated with boundary lubrication.

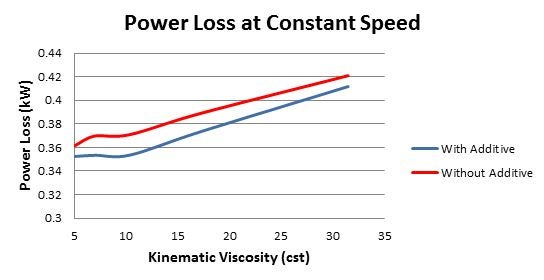

To further evaluate the effect of the friction modifying additive, power loss versus kinematic viscosity is plotted for both oils. This plot can be generated at each engine speed, with viscosity changing with oil temperature. When plotted for low speed, a curve is generated that roughly resembles a Stribeck curve. Although, this is not a true Stribeck curve as data points are not non-dimensional, it does share some similar characteristics such as the somewhat high friction at low viscosities, followed by a lower friction trough and then increasing friction as viscosity increases. True dimensionless parameters cannot be calculated here because the test engine consists of many rolling and sliding contacts all operating at different speeds and loads.

Additionally, some of the largest differences between oils are observed at lower viscosities, where boundary lubrication is expected. This method of analysis is useful in the comparison of oils with different viscosities since friction/power loss is plotted against viscosity.

Currently, a new test rig is being developed that will directly measure fuel consumption of a motorcycle engine operating at a variety of speeds, loads, and temperatures. The test rig uses a commercially available motorcycle engine which is coupled to a dynamometer. A computer system controls dynamometer load, throttle position, and other engine parameters. A photograph of the test rig can be seen in the following figure.

The data generated from these two tests will help Lubrizol’s engineers and chemists gain further understanding of friction reduction and fuel economy within the unique environment of a motorcycle engine. This knowledge will then be used to develop and optimize new highly fuel efficient lubricants for motorcycles.